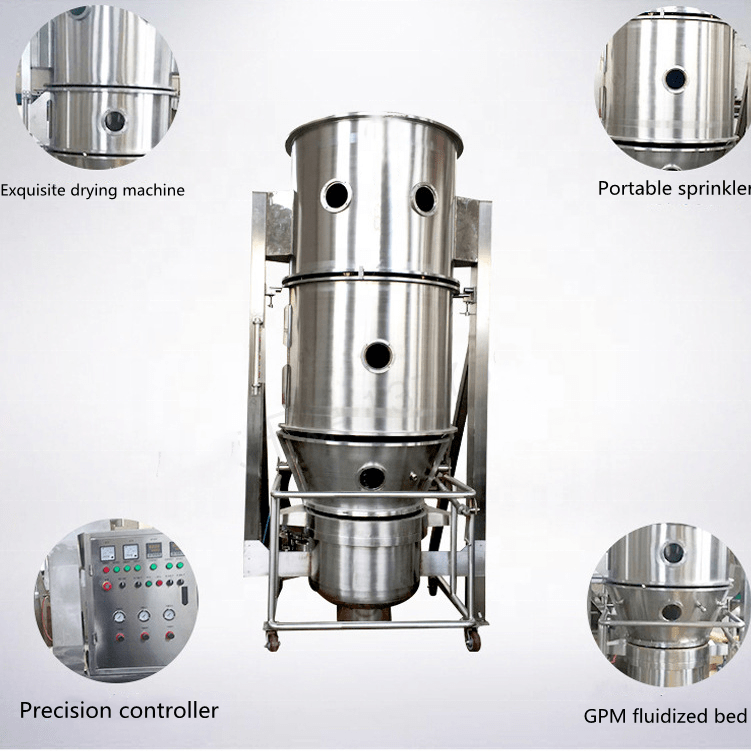

High Quality FL Series Fluid Bed Dryer Granulator Seasoning Flavouring Granules Drying Equipment

Seasoning Flavouring Granules Drying Equipment(FG series fluid bed dryer )is the special equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. By using powder granulation. Allpack fluid bed dryers can be used to improve the liquidity and thinner dust.

Description

Seasoning Flavouring Granules Drying Equipment

Seasoning Flavouring Granules Drying Equipment Principle of FL High-Quality Fertilizer Fluid Bed Dryer Granulator

The powder material is in a boiling state in fluid bed, heated and mixed by filtered hot air. Then spray binder into fluid bed, make the dry powder material agglomerate and become granules. The moisture in granule is evaporated by hot air and binder is solidified. Finally, the ideal, uniform and porous finished granule will be got.

Seasoning Flavouring Granules Drying Equipment Features of FL High-Quality Fertilizer Fluid Bed Dryer Granulator

Because of powder granulating, the flow property is improved and the dust is reduced.

Because of powder granulating, its solving property is improved.

The mixing, granulating and drying could be completed in one machine.

Being adapted anti static filter bag, the operation is safe.

There is explosion releasing hole to keep the people’s security when explosion.

The equipment has no dead corner, easy for feeding, discharging and clean. It could meet the requirement of GMP.

| Model | FL-3 | FL-5 | FL-15 | FL-30 | FL-60 | FL-120 | FL-200 | FL-300 | FL-500 | FL-800-1000 | |

| Container | Volume(L) | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 | By Client |

| Diameter(mm) | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | ||

| Capability | Min(kg) | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 450 | 750 | |

| Max(kg) | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | ||

| Fan | Air capacity(m³/h) | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 | |

| Air pressure(mmH₂O) | 375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | ||

| Power(kW) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | ||

| Steam consumption(kg/h) | 15 | 23 | 42 | 70 | 141 | 211 | 282 | 366 | 451 | ||

| Compressed air consumption(m³/min) | 0.9 | 0.9 | 0.9 | 0.9 | 1 | 1 | 1.1 | 1.5 | 1.5 | ||

| Weight of the main body(kg) | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2000 | ||

| Steam pressure(Mpa) | 0.3-0.6 | ||||||||||

| Temperature(℃) | adjustable at the range from room temperature to 120℃ | ||||||||||

| Working time(min) | 45~90(Depends on material properties) | ||||||||||

| Material Collecting Rate(%) | ≥99 | ||||||||||

| Noise(dB A) | ≤75dB(A) (When installation,main machine is separated from fan) | ||||||||||

| Overall Size(L*W*H) | 1.0*0.6*2.1 | 1.2*0.7*2.1 | 1.25*0.9*2.5 | 1.6*1.1*2.5 | 1.85*1.4*3 | 2.2*1.65*3.3 | 2.34*1.7*3.8 | 28*2.0*4.0 | 3*2.25*4.4 | ||

Title goes here.

Phamaceutical industry: tablet, capsule, low sugar or no sugargranule of chinese medicine.

Foodstuff: cocoa, coffee, milkpowder, juice of granulate, flavoring and so on.

Other industries: peticide, feed chemical fertilizer, pigment, dyestuff and so on.

Pharmaceutical industry: power or granule material.

Coating: Granule, protecting coat of pellet, spare color, slowrelease film, bowel-dissolve coating, etc.

Foodstuff: cocoa, coffee, milkpowder, juice of granulate, flavoring and so on.

Other industries: peticide, feed chemical fertilizer, pigment, dyestuff and so on.

Pharmaceutical industry: power or granule material.

Coating: Granule, protecting coat of pellet, spare color, slowrelease film, bowel-dissolve coating, etc.

Jiangsu Changshi Drying Technology Co., Ltd specializes in design, production and development of mixer, dryer, crusher, granulator, vibrating screen, dust collector and conveyor. The company has modern standard workshop buildings, engineering and technical personnel with medium and senior titles, more than 10 sets of processing equipment.The specialty provides complete set of powder equipment and solutions. In accordance with the GMP certification standard, the whole process of service is provided.

Multiple sets of advanced and sophisticated equipment

Complete and strict production control to be ensure the quality

Clean and tidy warehouse management

Seasoning Flavouring Granules Drying Equipment Service before sell:

—-Provide relative technical data for help equipment selection—-Running pilot test—-Offering advice for equipment selection, material analysis—-Provide flow chart, basic drawing—-Provide technical design

Seasoning Flavouring Granules Drying Equipment Service in sell:

—-Provide factory layout according to contract—-Manufacturing ordered equipment according to the related standard—-A presentation report of manufacturing situation will be offered every 15days—-Tracking and supervising in whole manufacturing and transporting period according to the contract requirement—-Photo of wooden case will be offered, wooden case with standard shipping marks.—-Photo of freight loading will be offered.—-A record of detailed delivery list will be offered—-A record of detailed freight loading list will be offered—-All of wooden case will be marked serial number, all of attachments will be marked serial number, convenient for client’s clearing

Seasoning Flavouring Granules Drying Equipment Service after sell:

—-Send service engineer for help instruct installation.—-Send service engineer for running test at site and training the operator—-Help client for maintenance and repair—-Provide one year spare part—-Quality warranty for two years after sell

1.Can I use this machine to extract some raw materials?

Yes, in order to help you better, we suggest you provide the name of the raw material you want to process. 2.Can I use my own raw materials for extraction test? Yes, of course. We can do extraction tests and send videos and test reports for your reference. 3.Do you have OEM service? Do you provide parts? Yes, we will, as long as you provide us with your drawings and detailed requirements. 4.How can we visit your factory? You can fly to Changzhou airport, or if you arrive in Shanghai, you can tell us your specific location. We will arrange a driver to pick you up. 5.How to transport equipment? We usually choose sea transportation. Laboratory models can be shipped by air according to customer requirements. 6.What is the voltage of the equipment? The equipment voltage is 110V~380V, the specification can be customized according to the voltage standard of the country where your equipment is used.

Reviews

There are no reviews yet.