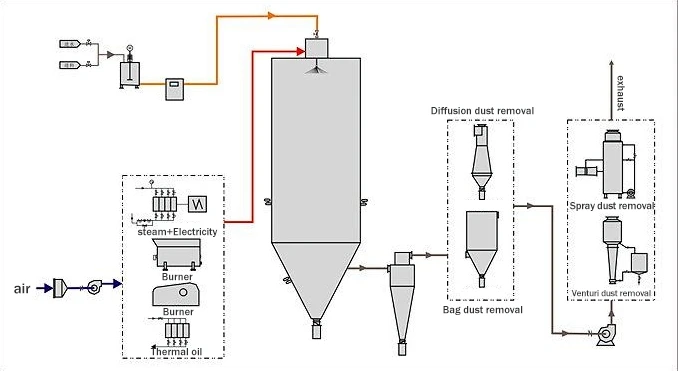

YPG Series Organic Catalysts Granulation pressure spray Drying machine

YPG Series Organic Catalysts Granulation pressure spray Drying machine : Spray drying process is the widest used in the liquid forming process and in drying industry. The drying technology is most suitable for powder, particle products from materials, such as,solution, emulsion, SC and pumpable paste states material. For this reason, when the particle size and distribution of the final product, their residual water contents, the stacking density and particle shape must meet the precision standard, spray drying process is one of the most desired processes.

Description

| Pressure Spray Granule Drying(YPG Series Organic Catalysts Granulation pressure spray Drying machine) | ||||||||

| Model | YPG-25 | YPG-50 | YPG-100 | YPG-150 | YPG-200 | YPG-300 | YPG-500 | YPG-1000-2000 |

| Evaporation Capacity(kg/h) | 25 | 50 | 100 | 150 | 200 | 300 | 500 | The index depends on the practical situation. |

| Overall Dimension(Diameter*Height)(mm) | 1300*7800 | 1800*9200 | 2400*11600 | 2600*14000 | 2800*15300 | 3200*17100 | 3800*19000 | |

| Power(kW) | 15 | 22 | 28 | 30 | 37 | 42 | 50 | |

| High-pressure Pump Pressure(Mpa) | It can be adjusted from 0.6 to 5 according to the material. In general, the pressure will be between 1 and 3 | |||||||

| Heating Resource | Electricity | Electricity+Steam | Electricity+Coal fuel (oil) hot air furnace | |||||

| Inlet Air Temperature(℃) | 300-350 | |||||||

| Product Water Contents | ≤5% | |||||||

| Material Restoration | >97% | |||||||

Chemical industry: organic catalyst, resin, synthetic washing powder, oils, thiamin, dyestuff, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on

Organic Catalysts Granulation pressure spray Drying machine Service before sell:

Organic Catalysts Granulation pressure spray Drying machine Service in sell:

Organic Catalysts Granulation pressure spray Drying machine Service after sell:

1.Can I use this machine to extract some raw materials?

Reviews

There are no reviews yet.